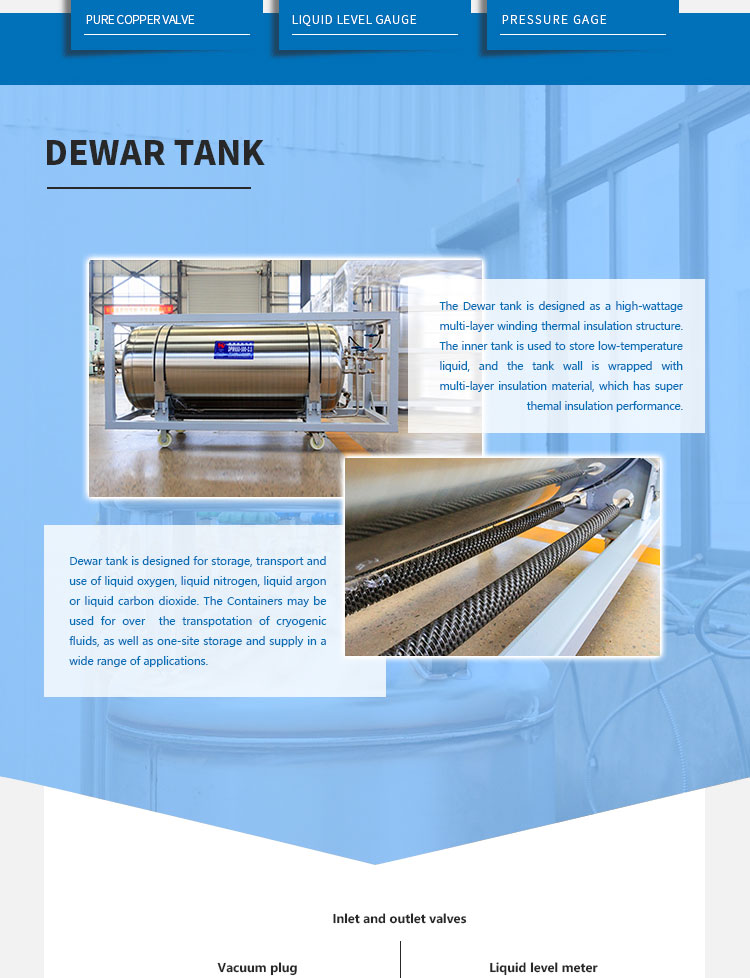

500L Horizontal Type Cryogenic N2O Dewar Liquid CO2 Cryogenic Tank

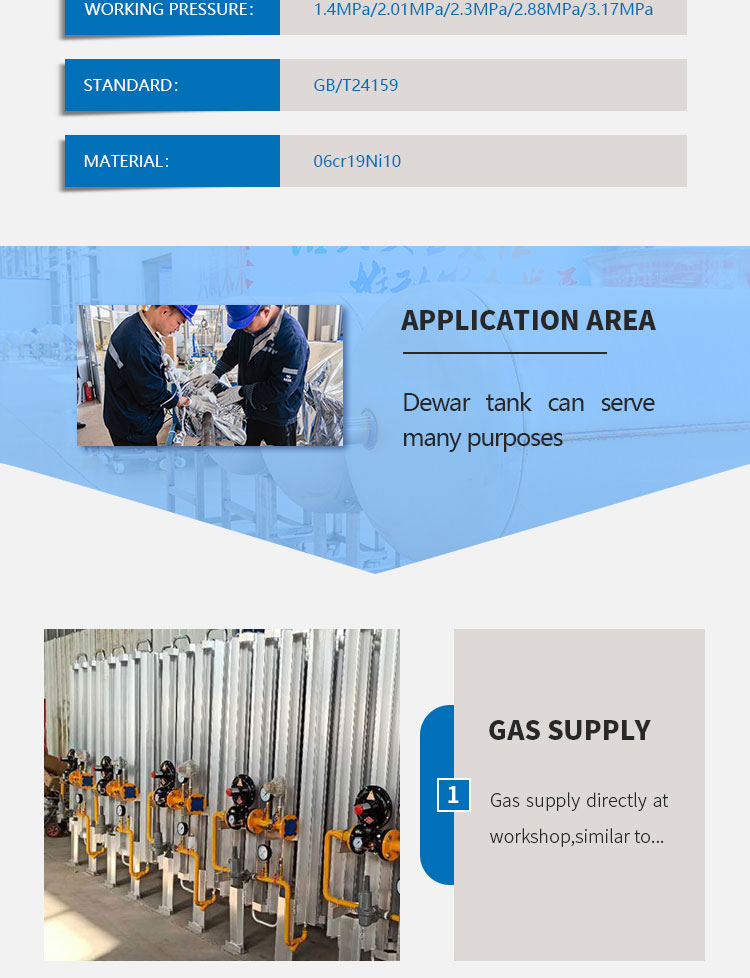

Dewar tanks are stainless steel pressure vessels with super vacuum insulation, designed for storage, transportation and use of liquid oxygen, liquid nitrogen, liquid argon or carbon dioxide. Manufactured to DOT4L standards, these vessels are used for reliable and economical transport and storage of cryogenic liquid gases, as well as on-site storage and supply of cryogenic liquid gases in a wide range of applications.

- YA

- Shandong province,China

- About 20 days after received orders

- 30000pcs per month

- Information

- Video

Dewar tanks are stainless steel pressure vessels with super vacuum insulation, designed for storage, transportation and use of liquid oxygen, liquid nitrogen, liquid argon or carbon dioxide. Manufactured to DOT4L standards, these vessels are used for reliable and economical transport and storage of cryogenic liquid gases, as well as on-site storage and supply of cryogenic liquid gases in a wide range of applications.

Advantages of Dewar tanks:

◆The storage pressure is low, multi-level safety protection device is set, the safety is better, and the operation is simple and reliable.

◆Large storage capacity, the gas storage capacity of a hexagonal gas cylinder is equivalent to nearly 30 cylinders of cylinder gas (oxygen, nitrogen, argon). Therefore, the storage area can be reduced, the operation of changing bottles can be reduced, and the work efficiency can be improved. For the centralized gas supply of pipelines, the investment in busbars can be reduced.

◆The bottle body is clean and the purity of the supplied gas is higher. Because the liquid gas is directly vaporized and supplied, it avoids the potential quality hazards caused by secondary pollution due to many links in the process of cylinder gas filling, transportation and use. Usually output oxygen purity ≥99.2%, nitrogen purity ≥99.999%, argon purity ≥99.995%, carbon dioxide purity ≥99.9%.

◆High utilization rate of gas: After each use of cylinder gas, there must be residual pressure, while the liquid gas supply of the hexagonal gas cylinder can avoid any waste and reduce the cost of gas consumption.

◆The self-weight of the hexagonal gas cylinder is about 116Kg, and the total weight after being filled with liquid gas is about 300Kg, while the total weight of compressed gas in 30 cylinders with the same amount of gas is nearly 2000 Kg. Therefore, the auxiliary cost of transportation and manual loading and unloading can be greatly reduced.

◆With automatic pressure boost control, circuit saving, built-in carburetor, pressure and liquid level indicating device, high integration.

◆It does not need any kinetic energy, is not affected by power outages and water outages, and can work around the clock.

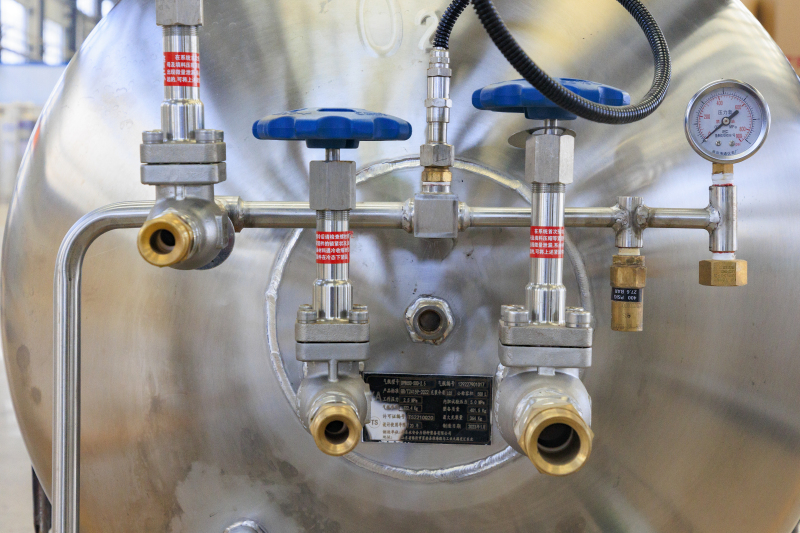

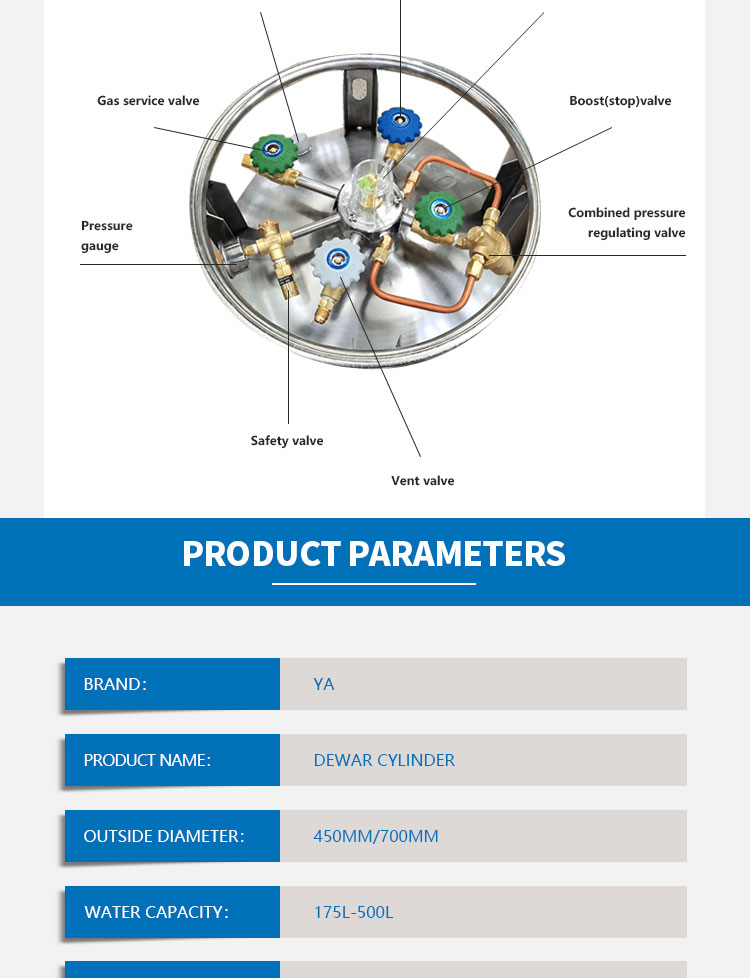

External structure of Dewar tank: Dewar tank generally has four valves, namely, liquid use valve, gas use valve, vent valve and booster valve. In addition, there are gas phase pressure gauges and liquid level gauges. When the Dewar tank is stored and not in use, remember not to open the booster valve. Be sure to check whether the booster valve is closed, otherwise it will cause gas leakage in the tank. The Dewar tank adopts high-vacuum multi-layer insulation, with a volume of 170-200L, which is convenient for the transportation and use of a small amount of cryogenic liquid. It is a new choice to replace the traditional high-pressure bottled gas transportation and use.