2 dead, 3 injured, oxygen cylinder explosion, the scene is tragic! Poorly managed gas cylinders are time bombs!

2023-07-19 10:01

At 15:15 on July 11, Harbin City Fire and Rescue Detachment Hulan Brigade received an alarm, Hulan District, China Road Town, too hutong a private house explosion of oxygen cylinders, Dongzhi Road Fire and Rescue Station dispatched 2 fire engines, 10 fire and rescue personnel rushed to the scene to deal with.

After reconnaissance, the scene for the oxygen cylinder explosion, no open fire, no personnel trapped.After preliminary understanding, the accident caused a total of two deaths (one of them died on the spot, one died after rescue), three people were injured, the injured have been sent to the hospital for treatment.

At present, the specific cause of the accident is under further investigation.

Cylinder use safety precautions

1、Correct operation, prohibit impact

● High-pressure gas cylinders should be opened slowly when opening the valve, the medium is a flammablegas cylinders should pay particular attention to prevent the high temperature generated at high speed orstatic electricity caused by combustion or explosion.

● Prohibit striking the valve and the cylinder with metal tools to avoid sparks or damage to the valve.

● Do not touch or operate the oxygen cylinder with grease-stained gloves or tools.

● Prohibit the cylinder from being struck, as this may damage the cylinder and shorten its service life, andmay also damage or loosen the valve stem, resulting in leakage of the medium inside the cylinder. Gasesthat are chemically active may also decompose and explode when the cylinder is hit, such as acetylenecylinders. Acetylene cylinder in use, is strictly prohibited lying.

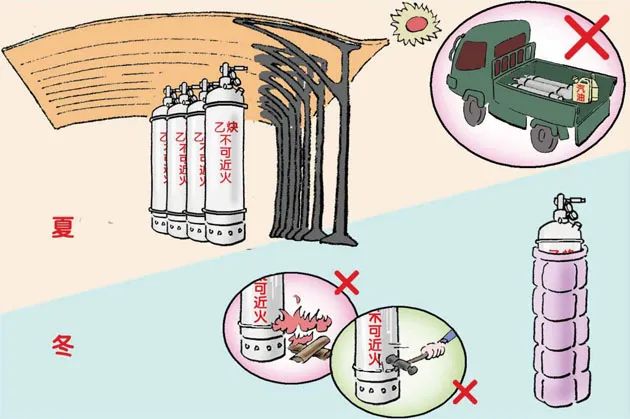

2. Keep away from open fire and prevent from heat

● The pressure inside the cylinder rises as the temperature rises,so in use, prevent the cylinder from beingbaked by an open fire,exposed to the sun, and close to heat sources such as steam pipes and radiators sothat the cylinder is exposed to heat.

The distance between cylinders and open flames and heat sources should be more than 10 meters. If theconditions are limited, heat insulation measures should be taken, but not less than 5m.

● Acetylene cylinders should not be near electrical equipment.

● When the valve freezes in winter, or when it is necessary to accelerate the gasification of liquefied gas, itis strictly prohibited to bake it with open fire, and it is not allowed to spray the cylinder directly with steam.The cylinder can be moved to a warmer place or thawed with warm water, the water temperature should becontrolled within 40℃.

3、Dedicated cylinders, leaving a residual pressure

● In order to prevent chemical explosions from occurring when gases of conflicting nature are mixedtogether, gas cylinders should be used exclusively for special purposes, and should not be converted toother gases without authorization.

● material back-up is the main cause of chemical explosions, in order to prevent back-up, the use of gascylinders prohibit the use of vacuum pump pumping, the gas in the bottle shall not be completelyexhausted, there should be a residual residual pressure to prevent the inhalation of air or other substances.Cylinders with residual pressure is also convenient for filling units to carry out inspections.

4、Civilized transportation and proper fixing

The cylinders should be loaded and unloaded lightly, and it is strictly forbidden to roll, throw, pour andother rough ways, and it is appropriate to use special trolley for handling in the factory, and it is forbiddento use electromagnetic crane to handle the cylinders. When loading gas cylinders, they should be placedhorizontally with their heads facing one side, the caps should be screwed tightly, and anti-vibration ringsshould be prepared. All cylinders should be fixed properly to ensure that they will not be tipped over ordropped during transportation to avoid damage.

5. Maintenance and periodic inspection

The paint on the outer wall of the gas cylinder is not only a protective layer against corrosion,but also amark for identifying the gas cylinder. It indicates the type of gas contained in the cylinder to preventmisuse or mixing. Therefore, it is important to keep the paint color intact and the lettering on thecylinder clearIf the paint color is peeling off and the characters are blurred, the cylinder should be repainted accordingto the regulations, otherwise the filling unit will refuse to fill the cylinder.Cylinders with cracks, leakage or obvious deformation on the cylinder wall, cylinders that cannot be usedaccording to the original design pressure after strength calibration, and cylinders that have been burned by fire should be scrapped in principle and cannot be used further.